Paper Cores are cylindrical shaped cardboard tubes that act as a base for certain materials which can be wound around the tube. Paper cores are also called industrial tubes, cardboard tubes, spiral wound paper cores and fiberboard cores.

These Tubes are used for many applications. Paper towel rolls, chart rolls, cable reels and many other widely used items are wrapped around these cores. Industrial cores are manufactured on the basis of the demand of the customer in accordance to their requirement and necessity. These tubes are mostly used in fabric, adhesive, electrical, paper products and converting industries as a suitable base around which material can be wrapped for shipping, storing or spinning.

Construction

Most manufacturers of paper cores use similar methods to create their cores. It takes just a few hours in the manufacture of paper cores.

- The process begins with collecting some amount of wood pulp in a container.

- The pulp is then broken down into minute pieces with the help of a machine.

- Different chemicals are added to these pieces that make the paper mushy, smooth, strong, and evenly-colored.

- The newly formed pulp is passed through a conveyor to remove moisture from it.

- The pulp is then molded into desired shape and size (mostly cylindrical) and dried completely.

The pulp tends to remain in the given shape but sometimes the industry coats the inner pulp with a layer of cardboard or some other material for additional strength. The end product or the tube is then cut according to the requirement and is ready to use.

Advantages of Industrial Tubes

There are plenty of alternatives of paper cores available in the market. The industries still choose to use paper cores because:

- Environment Friendly – Paper core doesn’t contain any non-biodegradable element and is easily recyclable.

- Strength To Weight Ratio – As compared to its weight, paper cores provide both strength and practicality for multiple purposes in industrial and household uses.

- Less Shipping Costs – Lightweight paper cores reduce the shipping costs for industries without compromising with the protection of the material.

- Easy Packaging – Cylindrical tubes provide a flexible base to the material which makes it easy to pack.

- Sustainability – Paper tubes are highly sustainable and since it is made up of recyclable materials, it can be easily recycled or reused.

Uses Of Industrial Tubes

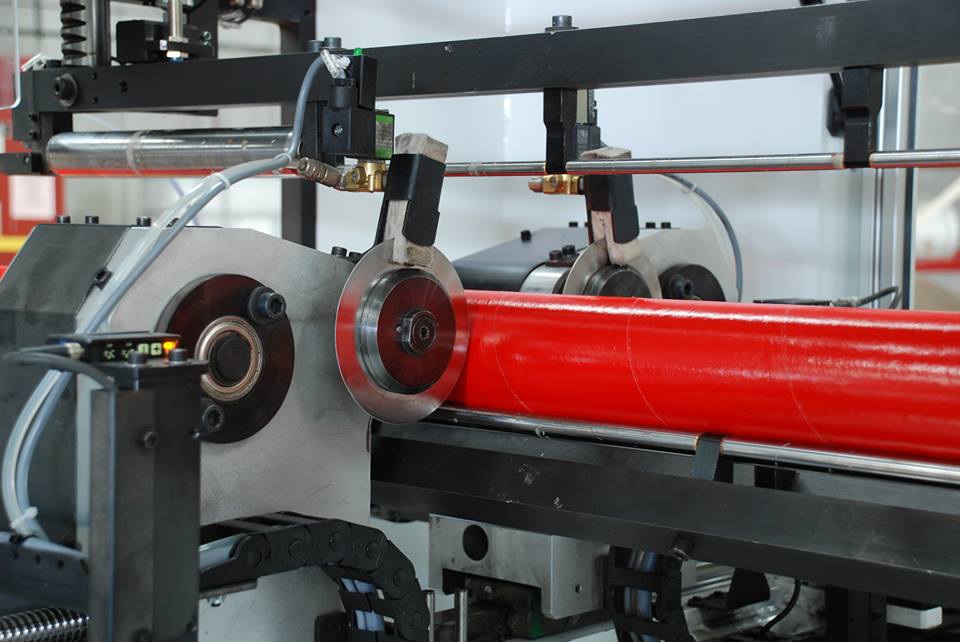

- Industrial Cores are polished to be used in polyester films and audio tapes. It helps in the rotation of the disc, without the tape being damaged.

- Industrial Cores are used in adhesive tapes. The outer surface of the core is polished with plastic or epoxy and the tape is winded over it.

- Industrial cores are the best way to handle wool and other natural fibre materials.

- It is used in the process of jute winding. Industrial cores are used to stretch raw jute and then wind them back .

- Small mechanical goods are kept in a medium sized core in order to prevent it from damage while packing and transportation.

- Industrial cores play an essential role in the manufacture of submersible pumps. It is packed in the paper core and then covered with perforated materials to prevent damage.

- Industrial core is primarily used in the manufacture and printing of newspapers. It is used while breaking the paper, thinning it and lastly drying it by rolling the rough edges of the paper core over it.

- Strong Industrial core is used in the packaging of beverages, alcoholic and non alcoholic.

- Industrial core is preferred over plastic core for adhesive tape wounding. It is more affordable and is easy to dispose of as compared to plastic core.

Foils are spun around Industrial cores which makes the waste generated by these foils considerably environmentally friendly.

A cardboard is a general term that is associated with the heavy –duty paper of various strength,ranging from a simple arrangement of sheets of paper to multiple layers.

A cardboard is a general term that is associated with the heavy –duty paper of various strength,ranging from a simple arrangement of sheets of paper to multiple layers.